A 200-hp Turboprop For Homebuilts

TurbAero’s tiny turboprop brings the strengths’¦and weaknesses’¦of turboprops to homebuilders.

Looking for a little more ramp appeal in your homebuilt? Is AvGas hard to come by at your home field? Or have you just always longed to be the one throwing the fuel to a turbine instead of just listening to the whine from afar as a turboprop comes to life? TurbAero is on site at AirVenture with a turboprop in development that might just give popular four- and six-cylinder homebuilt engines a run for their money.

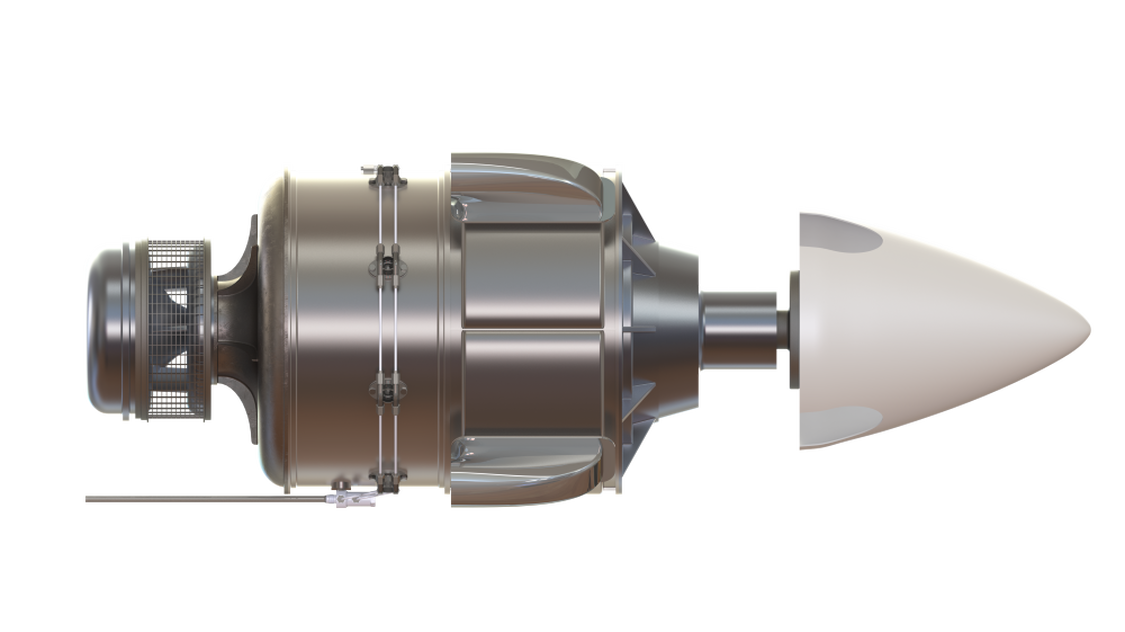

The TurbAero Talon TA200TP, which debuted this past summer at AirVenture 2021, aims to fill a niche that's a little less businesslike and maybe a little more weekend-warrior-ish. Rated at 200 shp for takeoff and 190 horsepower maximum continuous, it's looking like a turboprop could well decorate the nose of many common designs. Imagine the popular designs out there that could burn Jet-A and make power at altitudes above their current ceilings with normally aspirated engines.

Looking to the future, burning AvGas is problematic. Logistically, leaded fuels can't be transported in pipelines also used for unleaded fuel, and trying to distribute 100LL via truck is a tough proposition at best---and when the COVID-19 pandemic hit, we saw logistical resources directed, rightfully, to essentials for keeping people fed and warm. While the challenges of distributing AvGas domestically are a nuisance, internationally they're a downright nightmare. It's also a tiny segment of petroleum production that some argue is more trouble than it is worth. Throw in the environmental optics of leaded fuels and we recognize that the days of leaded aviation fuel may be numbered---and that number may be a lot lower than any of us realize. When you add in the growingly popular choice of biofuels, the options long-term look even more appealing.

On the downside, the engine, at around $80,000, itself will cost more than twice as much as a brand new, comparably powered Lycoming or Continental powerplant.

Another problem with turboprops is that in most general aviation designs, the benefits just aren't there. The specific fuel consumption involved up till now has relegated small aircraft powered by turboprops to a niche market of STC conversions that created a mission-specific aircraft. Loafing in the weeds or a Saturday in the pattern shooting landings just wasn't in their job description. They were designed to be loaded up and pointed in a straight line, at a proper altitude that usually involved oxygen, for a cross-country sprint.

On their website, TurbAero touts a fuel flow of 12.6 GPH while making 150 hp at 10,000 feet -- an altitude where a 200 hp, normally-aspirated engine would struggle to put out 100 hp. And with an installed weight that's about 20-40 pounds lighter than Lycoming's IO-360, you'd enjoy some weight reduction, but hopefully won't need to draw out a Pinocchio nose to make the weight and balance work, either. Expected TBO is set at 3,000 hours, which is a credible claim given turboprops simpler design and greater reliability compared with gas piston engines.

The company's website, www.turb.aero, has more information.

Subscribe to Our Newsletter

Get the latest Plane & Pilot Magazine stories delivered directly to your inbox