Where The Rubber Meets The Load

Sometimes, it’s not the obvious things that need attention.

Ask most any pilots how the rubber is holding up on their plane, and you'll most likely get a quick reply along the lines of, "Oh, the nose tire is good; one of the mains is a little worn. Overall, the rubber is okay."

As a new caretaker of an old airplane, I did have to replace a tire before our big trip west, but I also quickly realized there was a lot more rubber on the plane than I expected, and almost every bit of it needed attention!if not immediate replacement.

An Old Concept, But Still In Use

Many warbirds and many postwar aircraft had rubber shock mounts holding the instrument panel, or at least some portion of it, in place. Gyro instruments were often so mounted; delicate electronics also seemed to last longer when isolated from airframe vibrations. Our Mooney's pilot-side instrument panel rode on a handful of rubber isolation mounts---or at least it did originally.

The panel had visibly sagged a bit from where it should have ridden, but it wasn't sagging on the mounts; it was past that point. Instead, almost every mount had snapped---distorted with weight and embrittled with time---and only two out of the eight had any connection remaining from the panel to the supporting structure. The other mounts had broken completely and were purely in place to show me where the new ones should go. Gravity, a tight fit and the umbilical cords to the instruments had held everything in place for untold years. Nearly all modern aircraft have instrument panels that are solidly mounted to the airframe, and many Mooneys have been converted to a rigid setup as well. But it was easier just to use what came from the factory than to modify my setup at the time, so I tracked down some Lord mounts---yes, Lord makes those kinds of mounts, too---and replaced them all one afternoon. What surprised me was that the panel was actually resting on the row of circuit breakers. There's no telling if we were near electrical disaster or whether it was a non-event, but the idea of things rubbing the backside of circuit breakers certainly got my attention.

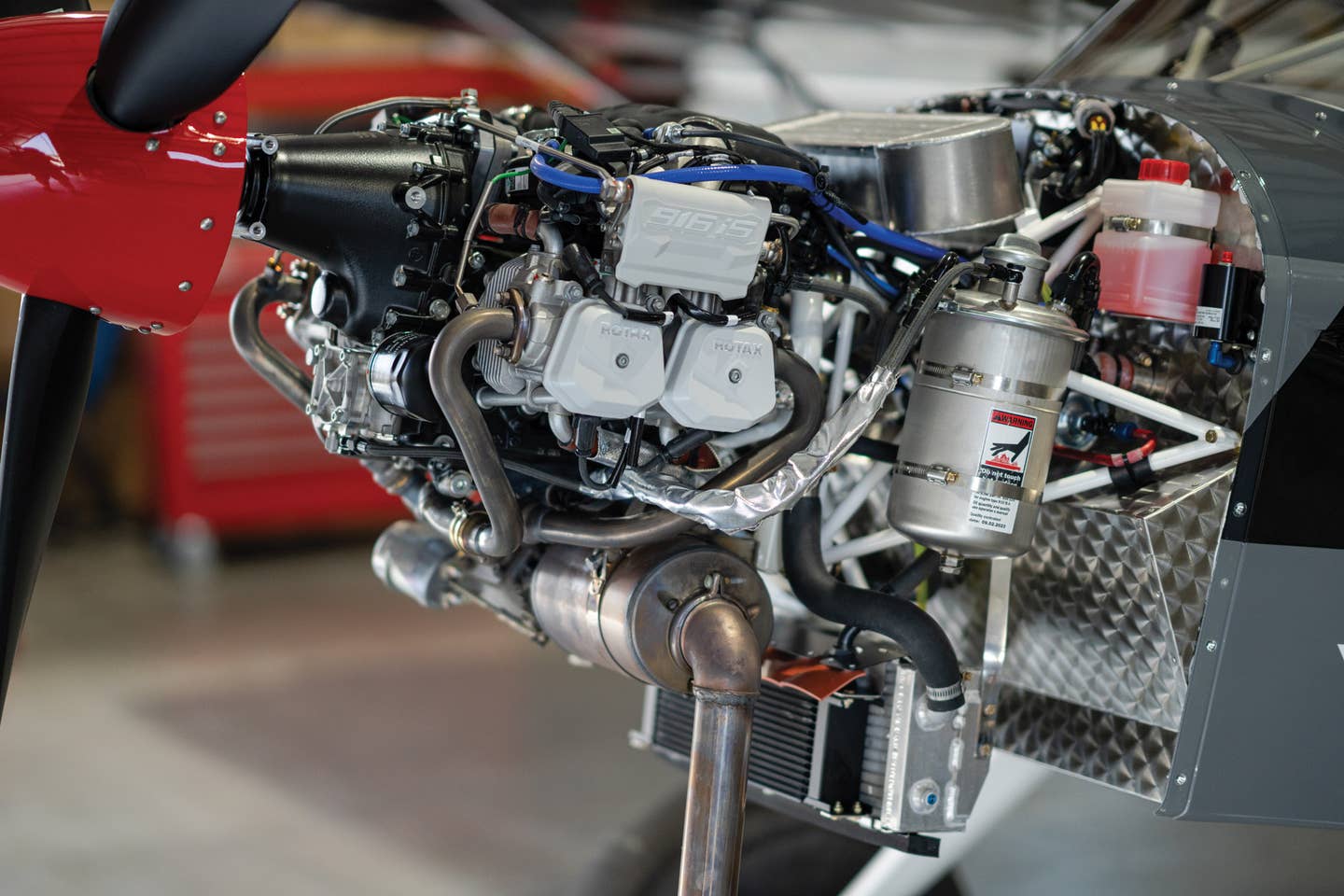

Engine Isolators

For as long as I can recall, certainly for several years before taking ownership of this bird, the spinner sat low within the nose bowl. And because the cowl is modified with the LASAR enclosure that cinches up the lower lip of the vintage Mooney "guppy mouth" inlet, the spinner doesn't sit centered top to bottom, even with new mounts.

Parked on the ramp in Kanab, Utah, I had a dummy's blueprint to study---an identical Mooney---and I asked the owner which cowl modification he had. It looked so dissimilar that I imagined it had to be something completely different. When he responded, "It's the LASAR mod, same as yours," I did a double-take. The positioning of his spinner was so distinct from mine that the difference in aesthetic was that drastic. It was time for new rubber there, too. On one of the last legs of our trip out west, I had the bird trimmed perfectly, and at the top of descent, I just slowly closed the throttle, expecting the nose to drop so as to hold the same airspeed. Instead, I was met by the nose climbing a few degrees---if the thrust angle was down enough to have that effect, it was probably shaving a few knots off the cruise speed. I ordered a set of Barry mounts to replace the aging rubber, and then I did what I do best---I parked the plane when we got home and procrastinated.

My former roommate Nick wound up with an Atlanta overnight, and I snagged him that morning for a work day at the hangar. I picked him up, and, with a rented engine hoist in the back of my Subaru, we ran out to the hangar for a work day. He's one of my mechanically inclined friends, and he didn't complain when I told him the plan.

Let me say this: A friend who will help change the engine mounts on a Mooney is the sort you should keep on your holiday card list. To change the isolators on a Cessna 172 with a very similar Lycoming O-360, it's a pretty straightforward process. Hook the hoist to the engine's lifting lug, loosen the nuts on the isolators, wiggle the engine enough to work out the old rubber, replace with new, and put it all back together.

Just getting the cowl and the doghouse---Mooney owner slang for the plenum that keeps the cooling air moving the right way over the cylinders---takes about as long as swapping the mounts on a 172. With the engine supported from the lifting hook, we had to unbolt the engine mount from the firewall, disconnect most of the wiring and controls to the engine, and slide the engine forward a couple inches. Like with the engine bay of a late-model sports car, space is at a premium, and the lower-left isolator bolt is an interference fit with the pilot's left footwell for the rudder pedals. Plenty of Mooneys are out there with holes drilled and patched where mechanics tried to make shortcuts for the process and wound up making a lot of extra work instead.

Nick and I are both first officers on the Airbus 320. Our hourly pay rate, if applied as a shop rate, would make the most expensive repair stations seem a bargain in comparison, but we weren't paying ourselves in anything other than the camaraderie of friends united in task while we caught up with the months since we last met and recounted the stories of some adventures we'd survived together.

I'd hoped to have Nick back to the hotel with time for a nap before he headed to the airport; instead, we managed to kill most of the day telling stories, dropping wrenches and knocking out one of my most dreaded projects on the Mooney.

And we had a great time doing it.

Extra-Tough Donuts

But wait, there's more. If you call now, we'll throw in one more unexpected place for rubber to age out and leave you in need of repairs.

There are no shock struts on a Mooney's landing gear, nor sprung steel landing gear legs nor bungee shock absorbers. Al Mooney, for whatever reason, drew up all three gear legs with a stack of rubber donuts to take the impact of landing. A believable---but unsubstantiated---rumor is that the original rubbers he used on the landing gear were Mack Truck engine mounts. Whether it's true or not is no longer really a matter of significance, as Mooney gear pucks have been upgraded to an aviation product in the years since, but the designer's eye for simplicity in an off-the-shelf solution rings true with so many other Mooney design elements. Some of the later (much heavier) Mooneys see these rubber pucks failing after just a year or two; the lighter models, like mine, can go a decade or so between replacement. I was reading a thread on a Mooney owner's forum in which a pilot discovered his pucks were pretty darn old, and I made a note to myself: "Self," I thought, "The next time you go fly, look for a date code on the landing gear donuts."

The donuts didn't look distorted or significantly cracked, so I hadn't paid them much mind before. But they're much of the airframe's shock absorption for my landings, and the runway where the gray gal lives is unquestionably rough. An undesired side effect as the pucks age and harden is the landing shock is transmitted through the nearest airframe structure, which happens to be the sealed bays of the wing that make up the fuel tank. The older the fuel sealant gets, the more brittle it becomes, and resealing the tanks is close to a $7,000 job last I checked.

So, the more I dwelled on it, the more important checking the rubber donuts became. On my next preflight, after draining the fuel sample from the right tank, I rolled over and squinted at the pucks, looking for a date code, hoping to at least see something produced this century. Within the last decade would be even better.

I turned my head sideways, figuring the date code had to be upside down. I squinted until the world went dark, then opened enough to let just a little light through. I tried to read it backward, forward, sideways and in pig Latin, but the only way I could make the date code work was to admit the painful truth that the rubber on my landing gear, the pieces that really should be taking much of the shock from repeatedly planting this bird on the side of a bumpy hill, were more than a decade my senior, manufactured in 1969.

Now, if I can just trick my buddy into another Atlanta overnight.

Subscribe to Our Newsletter

Get the latest Plane & Pilot Magazine stories delivered directly to your inbox