Learning To Trust Turbos

Once regarded by some pilots as inventions of the devil, turbochargers have gained respectability

|

Like the vast majority of pilots, I learned to fly in a relatively innocent two-seater. It was a Champion Tri-Traveler, basically an Aeronca Champ that someone decided would be better off with a nosewheel. Bad idea. The airplane was obviously embarrassed, but in combination with a truly decrepit Piper Colt and 63 hours of patient training by a half-dozen instructors, it somehow earned me the private license.

Not too long after that, I was introduced to twins in a Twin Comanche and, eventually, a near-new Seneca II. The Seneca II was my company airplane for three years, flying out of my home in Southern California for a Midwest publishing company that specialized in producing corporate magazines. It was my first experience with turbocharging.

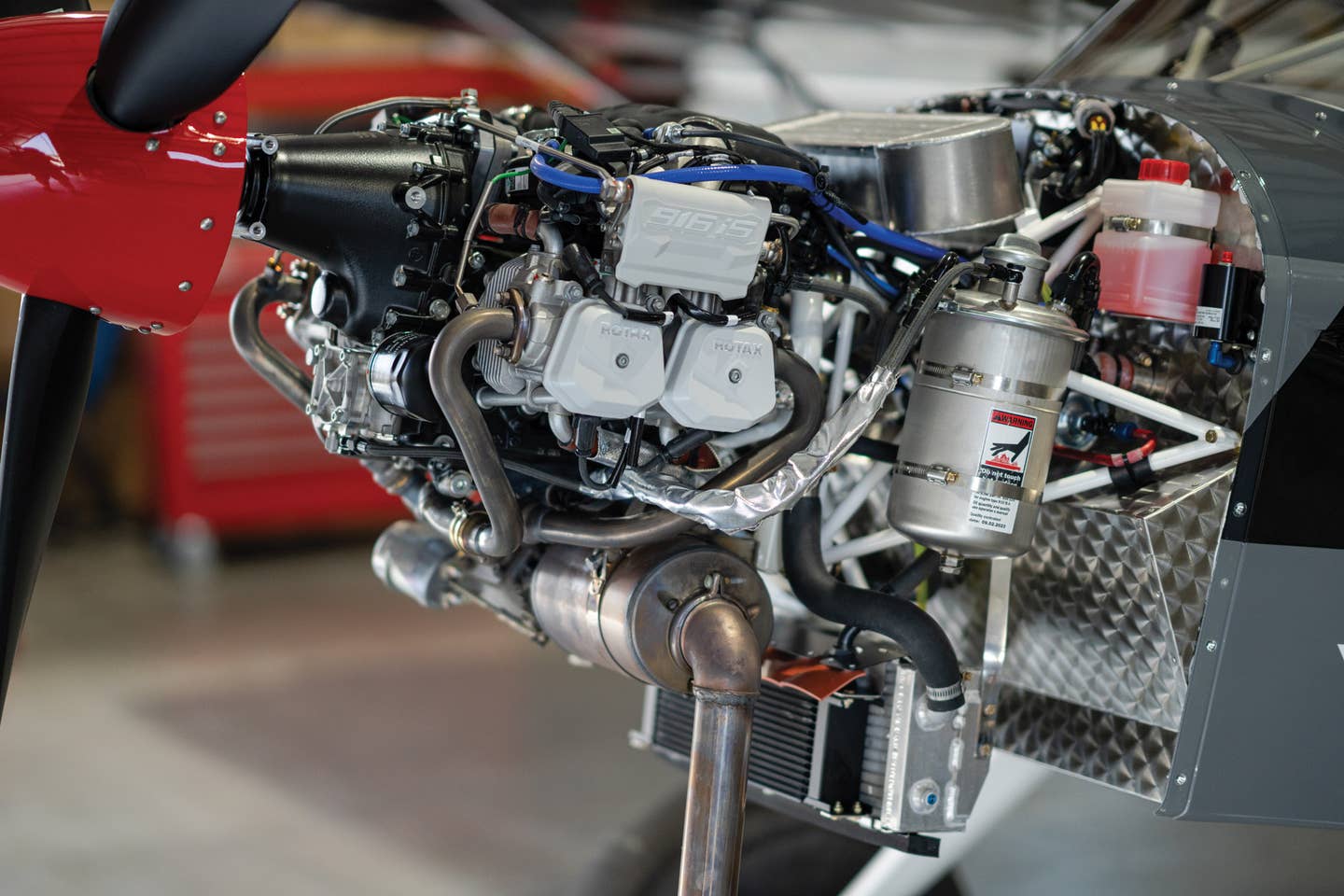

As you might imagine, turbocharging, like most things in aviation, is far from new. The concept is almost silly simple, but the execution is considerably more complex.

In its simplest form, a turbocharger is little more than an air compressor driven by exhaust gas. GE installed a turbocharger onto a 350 hp Liberty engine in 1918 and carried it to the top of Pike's Peak (at 14,000 feet MSL) where the engine put out 356 hp. A standard Liberty forced to run at that height could be expected to generate only about 210 hp.

Only three years later, an intrepid Army aviator, Lt. J.A. Macready, established a new altitude record of 34,504 feet using a modified Lapiere biplane flying with a boosted Packard engine.

Despite GE's experiments and Macready's brave flights, turbocharging didn't really catch on until the 1940s, when World War II finally jumpstarted the technology. For better or worse, war nearly always precipitates quantum leaps of innovation. The system was installed on a variety of American fighters and bombers during World War II, most notably, the P-38, P-47, P-51, B-17 and B-29.

Turbochargers and superchargers were seen as a shortcut to deliver more power at high altitude without adding weight or unnecessary complexity. This was especially critical in the European theatre of operations where weather often forced bombers and the accompanying fighter support aircraft to fly high. Using compressed air helped make that possible. Turbos were also popular on helicopters that sometimes needed to operate from high terrain without a loss of power.

After the war, turbo technology slowly trickled down to general aviation. By the 1960s and 1970s, it was being installed on a variety of singles and twins, and the Rajay compressors on those early Comanches, Twin Comanches, Seneca IIs, Turbo Arrows and a number of other airplanes were a mixed blessing. I visited the Rajay factory on Long Beach Airport in the '70s and was dismayed to learn that the company's aircraft turbos were nearly identical to those used on turbo-diesel trucks.

"My" Seneca II was one of the first 1975 turbocharged models. It had something like 1,200 hours on it after only two years in service. In fact, the folks at Piper told me it was the highest-time Seneca II they had seen at that time. It had been well maintained and professionally flown, but had already worked its way through three turbos, and I was to have another fail in the next three years and 700 hours of flight time. Right or wrong, that led to a certain distrust of the technology.

Not any more. Rajay, AiResearch and other turbo manufacturers have come a long way since those pioneer days. Modern engines enjoy turbocharged reliability that can equal that of the engine itself. A properly maintained turbo system can improve power exponentially and add a new dimension to aircraft performance with little increase in maintenance and operating expense.

In its simplest form, a turbocharger is simply an air compressor powered by what would normally be wasted exhaust gases. The compressor can supply the engine intake manifold with far more air than could be obtained with normal atmospheric pressure.

A supercharger achieves the same result by a slightly different route, but it's less efficient and is less popular. Superchargers are driven by the engine's crankshaft itself. This means superchargers are less efficient as they require power to generate boost, whereas turbocharging is regarded as "free." Unlimited air racers at Reno can pull as much as 100 inches of manifold pressure using superchargers.

Turbocharging comes in several forms, the most common being turbo-normalized and turbo-supercharged. A turbo-normalized turbo, as the name implies, allows the system to provide sea-level power to high altitude, whereas a turbo-supercharged engine may provide more than sea-level power.

Many of the early general aviation turbos managed to split the difference with a two-throttle system that simply allowed the second throttle to channel air to the intake manifold. The system was dependent upon the pilot to avoid overboosting.

I owned one of these systems on my Mooney Executive for several years through the 1990s and early 2000s, and it was easy to see how the extra power could be abused. For normal operations at low altitude, you left the second throttle in the full aft, disengaged position and the engine performed as if it was normally aspirated. As you climbed and the engine began to lose power, you pushed the second throttle forward to restore lost manifold pressure. During descent, you retarded the turbo throttle first, and power was reduced to ambient. After that, you reduced power with the normal aircraft throttle. Pretty simple, huh?

Problems arose if you forgot that the second turbo throttle was still forward and initiated another takeoff with the second throttle against the forward stop. In this situation, you could easily overboost the engine to 35-40 inches of manifold pressure---often for a very short time.

The engines weren't hardened for this much power, and the result could be a loud and dramatic explosion. The story goes that a salesman at a Washington state Lake amphibian dealership traveled over high mountains to reach a favorite fishing lake in the Canadian Rockies and forgot to retard the turbo throttle after landing. He caught his limit, then neglected to pull back the turbo throttle before his water departure from the British Columbia lake.

He pushed the throttle full forward, the airplane leaped up onto the step and into the air. The pilot experienced spectacular power for a few seconds, just long enough to climb a few hundred feet, before the engine blew. He was fortunate to get the airplane back onto the water before running out of lake.

Happily, that kind of failure couldn't happen today, with the advent of pop-off valves and governors. Automatic controllers now monitor power to assure it can never exceed the limitations of the engine.

If turbos have a downside, it's that the compressed air delivered to the induction system by the turbo(s) isn't always very efficient. It's extremely hot, often 250-300 degs F. An increase in induction air temperatures of 10 degs F decreases horsepower by about 1%. The solution was an intercooler, designed to reduce the temperature of turbo air before it was introduced to the cylinders.

The lesson is that turbochargers are no longer demons. You can fly behind them with confidence. Just remember to cool them down after landing. Some turbos spin at 50,000 rpm or more in cruise flight and are lubricated by the same oil that keeps the engine happy. Shut down the engine (and therefore the oil supply), and you shut off lubrication to the turbo. For that reason, standard wisdom is to let the engine run at idle for three to five minutes on the ramp to allow things to spool down, and your turbo will be happy, too.

Subscribe to Our Newsletter

Get the latest Plane & Pilot Magazine stories delivered directly to your inbox