Know Your Engine Inside And Out

High-quality lubricants play an important role in ensuring your aircraft has a long, healthy life

The cost of owning and operating an aircraft can be high. Whether you're a frequent flier, fly occasionally for pleasure or someone whose day-to-day job is flying an aircraft, having a reliable oil to protect against engine wear and prolong engine life is paramount.

The protection high-quality engine oils provide can help to reach or exceed time between overhaul (TBO) with minimum maintenance, and reduce operating and maintenance costs and overall fuel consumption. Certain cases have shown that engines protected by high-quality lubricants have been so clean and in such excellent condition that they have been given extensions on the aircraft's engine life, approved by the local authority.

The Benefits Of Lubricant Additives

Engine oils with anti-corrosion and anti-oxidation additives are key to protecting the engine and helping to increase TBO. Oils that fail to neutralize acids can allow acid particles to reach metal surfaces, resulting in harmful engine corrosion---if broken down by heat and acids, they could also fail to protect against wear and power-robbing deposits, leading to a decrease in TBO and and increase in costs.

Anti-scuffing additives can also better protect the engine's moving parts. A lubricant with sufficient wear protection plays a vital role in prolonging your plane's engine life. Without a high load-carrying capacity, an oil can fail to keep heavily loaded metal components apart and free from damaging metal-to-metal wear. Poor lubrication can even lead to excessive piston wear and unexpected maintenance costs.

Protecting Your Lubricant

If an oil flows too slowly on start-up, it may fail to reach and protect critical components, leading to high oil consumption and blocked oil-ways, causing oil starvation. The result is expensive damage, and in some cases, in-flight shutdown. Low oil pressure can occur over time due to viscosity loss or when the viscosity of the oil isn't suitable for the climate it's operating in. To maintain the viscosity of your oil, major OEM's recommend oil drain and oil filter change intervals every 50 hours, or every four months for engines fitted with full flow oil filters.

Choosing A Lubricant For Your Needs

When it comes to choosing specific lubricants and oils for their planes, pilots and aircraft owners look for the perfect balance between price and performance. But how do you tell which one will give you the best performance?

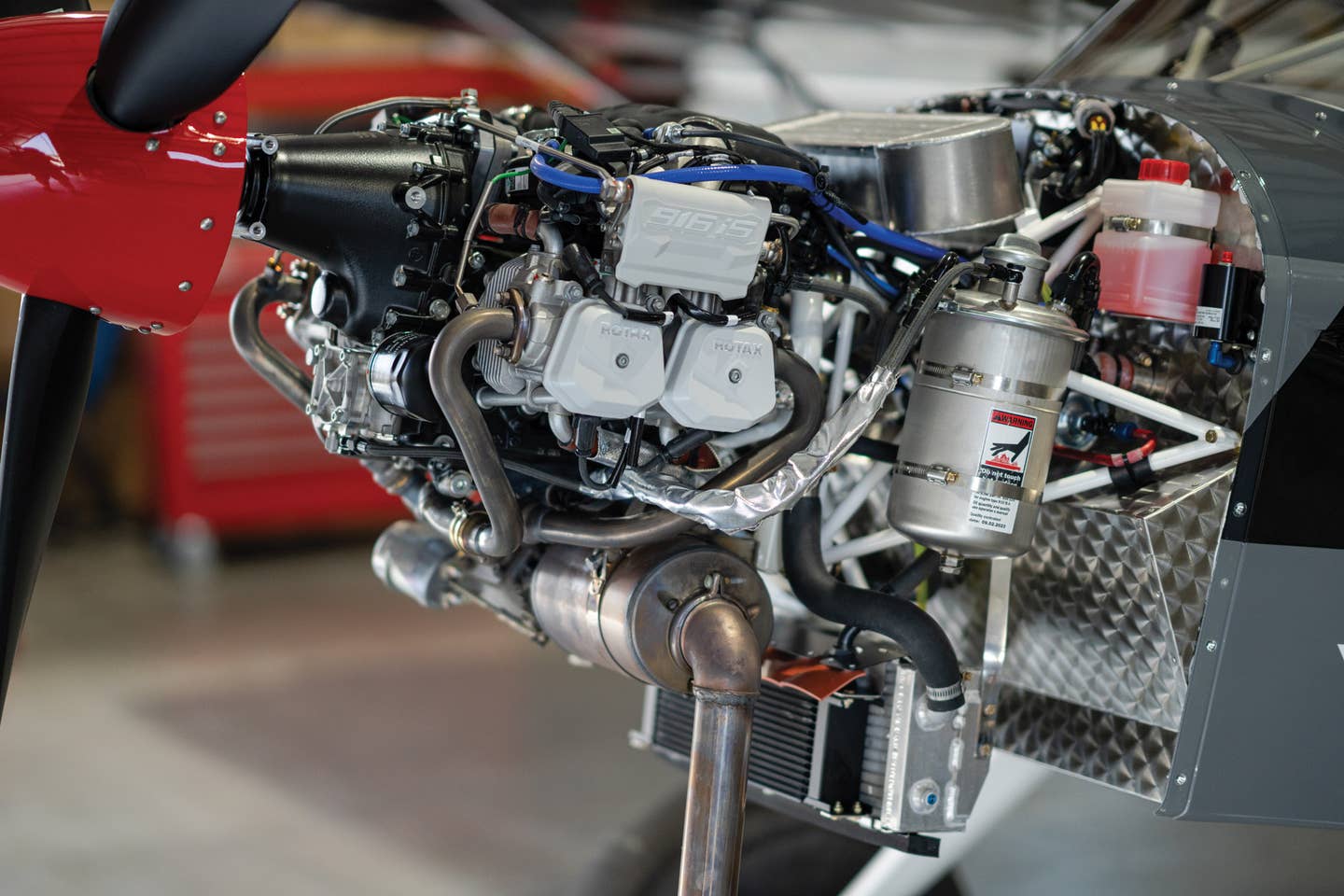

Aircraft piston engines each make specific demands on engine oil. Powerplants can be two- or four-stroke, gasoline/diesel-fueled, carbureted, fuel-injected or turbocharged, so it's necessary for lubricant suppliers to provide a comprehensive range of oils that are specially formulated to protect a variety of engine types. Choosing the best-performing lubricant for your aircraft depends on different factors such as the quality of the lubricant, the engine type and your flying experience, for example, frequency of flying or the climate you are flying in.

Innovative Lubricant Solutions

New lubricant formulas and technologies have been developed over the years in response to the ever-changing demands of engine specifications. In the 1950s, the first piston engine oils to use ashless dispersants for cleaner engines were introduced. These oils contain nonmetallic dispersant additives that help to avoid the build-up of metallic ash residues on critical engine components.

The 1980s saw the introduction of the first semi-synthetic, multi-grade aviation oil. The grade of an oil---either mono (e.g., W 80, W 100) or multi-grade (e.g., 15W-50) shows its viscosity---the lower the temperature the plane will be flying in, the lower the viscosity needed. By definition, single-grade (e.g., W 80, W 100) and multi-grade oils (e.g., 15W-50) both meet the same specification---both types of oil are designed to provide excellent service, offering the same rust and corrosion protection.

However, multi-grade oils remain almost constant as the temperature changes between a particular range. Their excellent high and low temperature performance can provide improved operation in extreme temperatures, allowing flying schools and pilots flexibility to fly at anytime in the year. With no need to change oil between summer to winter grades, maintenance schedules are simplified and idle time, fuel consumption and operating costs are reduced when compared with single-grade oils.

For pilots who fly less regularly or only during the summer months, a great advantage of the multi-grade oil is the protection it provides when the aircraft is stationary for an extended period of time. Pilots can trust that their engine will have complete protection from rust and corrosion in between flights and, most importantly, that it will be in pristine condition for their next outbound journey.

As it is for any aircraft, general maintenance is an important part of a flying schools' curriculum. When a student undergoes flight training, both the school and the student need to know that the engine is protected all year round, helping the student fly with confidence. For flying schools, having a lubricant supplier with a comprehensive range of oils is key to ensuring they meet the needs of each aircraft type.

In the 2000s, the first oil was developed in conjunction with major engine manufacturers specifically for light sport, very light and ultralight two- and four-stroke engine aircraft. It was developed to satisfy the specific demands of the small, four-cycle piston engines used in the light aviation sector, which previously relied on automotive lubricants. The new formulation offered improved anti-wear protection compared with previous oils, and enhanced protection and lubricity for smooth clutch and gearbox component movement. It was also designed to cope with the higher-bearing loads when burning jet fuel, helping to protect against corrosion, sludge and scuffing.

More recently, in 2006, fully synthetic piston engine oils were developed specifically for use in the new generation of compression-ignition engines burning diesel or jet fuel. All of these developments have shown that innovative lubricants will continue to be explored and created in order to meet the latest demands of engines.

Olivier Procès is regional technical manager for EMEA at Shell. Visit shell.com/aviation.

Subscribe to Our Newsletter

Get the latest Plane & Pilot Magazine stories delivered directly to your inbox