ICON Aircraft Production Update

As the ICON A5 moves closer to FAA approval and serial production, the ICON team continues to progress with assembly of the first production prototype A5

As the ICON A5 moves closer to FAA approval and serial production, the ICON team continues to progress with assembly of the first production prototype A5. Engineering Serial Number 1 (ESN1), currently being built at ICON's facility in Tehachapi, California, is the first of several planes that will support the FAA compliance audit for LSA airworthiness.

ESN1 is also the first aircraft from ICON to be manufactured using production tooling and is on target for completion later this year. In the third quarter of 2013, ICON's suppliers began manufacturing the hundreds of aluminum, steel, and carbon fiber molds Cirrus Aircraft is using to build the composite airframe components of the production A5. At the same time, other suppliers began construction of the assembly fixtures with which ICON is building the aircraft. To date, all airframe components and assembly fixtures have been received at ICON's facility.

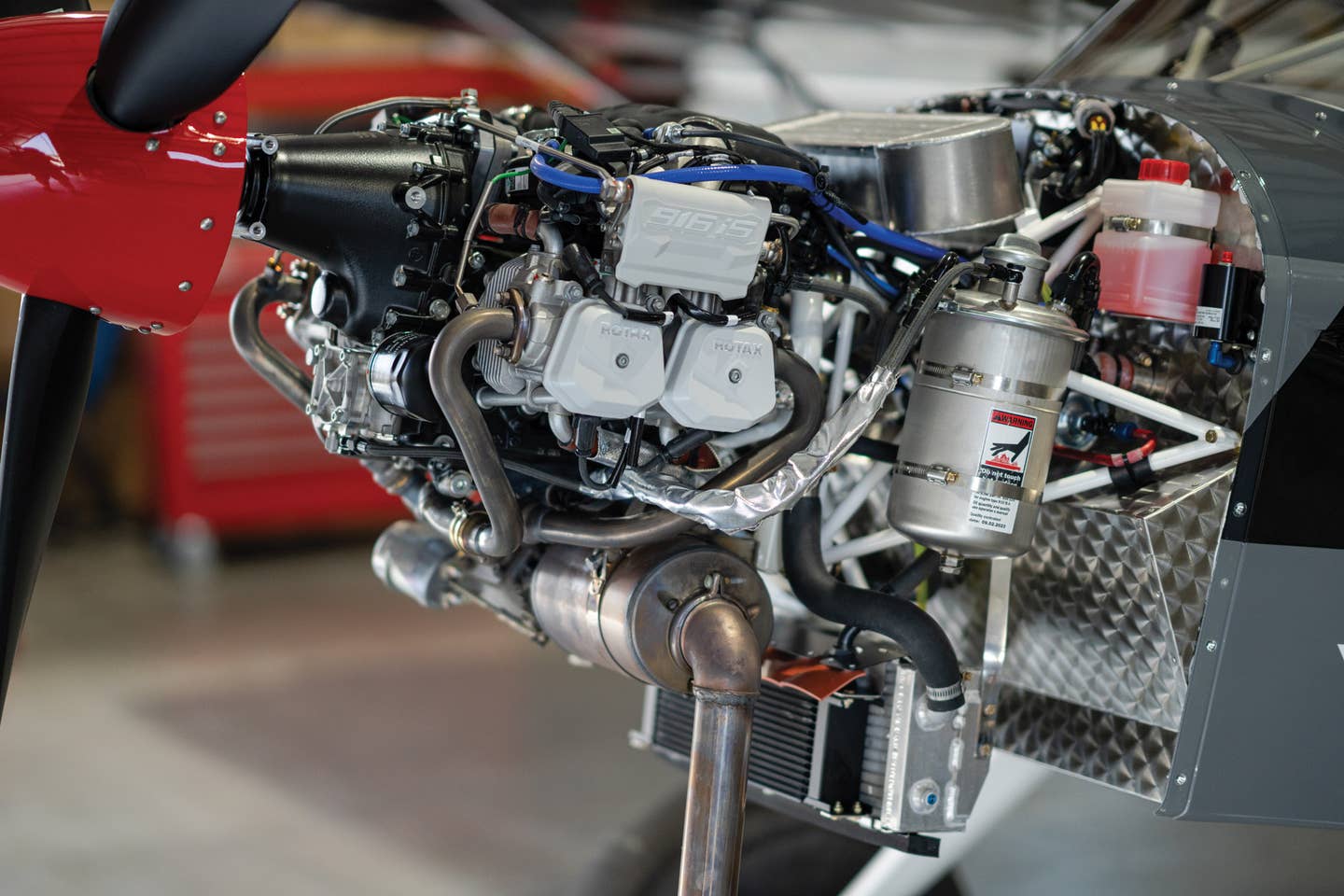

The build is currently focused on ESN1's structural composites, and ICON's technicians have begun bonding all major components of the airframe, including tail, fuselage, wings, control surfaces, and canopy. As the structure of ESN1 comes together, the team will transition its focus to systems integration, which includes the installation of electrical, propulsion, landing gear, interior, and parachute systems.

Visit www.iconaircraft.com.

Subscribe to Our Newsletter

Get the latest Plane & Pilot Magazine stories delivered directly to your inbox