Glass-Cockpit Blackout

Dealing with electrical failure while trying to maintain aircraft control

The NTSB doesn't just investigate accidents; it also routinely examines incidents to determine whether they expose an underlying safety problem, which, if not addressed, could set the stage for future accidents. Recently, it examined an incident involving an Airbus A320 operated by United Airlines. This led to the discovery that there had been at least 49 similar incidents in the United States and the United Kingdom. In response to its own investigation, the NTSB issued a safety recommendation, hoping to encourage FAA action.

The NTSB doesn't just investigate accidents; it also routinely examines incidents to determine whether they expose an underlying safety problem, which, if not addressed, could set the stage for future accidents. Recently, it examined an incident involving an Airbus A320 operated by United Airlines. This led to the discovery that there had been at least 49 similar incidents in the United States and the United Kingdom. In response to its own investigation, the NTSB issued a safety recommendation, hoping to encourage FAA action.

Regardless of the FAA's reaction, the recommendation should raise awareness of a broader issue for pilots flying technologically advanced aircraft (TAA): How to best deal with electrical failure and the subsequent loss of vital information from display screens while maintaining aircraft control and situational awareness. Pilots must be thoroughly trained in equipment operations, particularly with respect to emergency procedures. They must also learn not to become overly reliant on modern equipment, allowing it to replace basic flying, navigation and judgment capabilities. [Visit our Proficiency section for expert advice on maintaining your flying skills.]

In the past, many electrical-failure incidents became accidents not because of the loss of panel information, but because pilots didn't realize that there wouldn't be enough power to operate the flaps and landing gear until it was too late to plan a no-flaps landing and perform emergency procedures.

On July 11, 2007, at Washington's Roche Harbor Airport, a Cessna 172RG's landing gear collapsed just after touchdown, resulting in substantial damage. Nobody was injured. The pilot said that as he approached the vicinity of Roche Harbor, the airplane experienced a partial electrical failure. He decided not to attempt to troubleshoot the problem, and elected to land quickly for fear of a possible electrical fire. After activating the landing-gear handle, he was able to ascertain that the gear was extended by looking in mirrors affixed to the wings. The landing-gear lights on the panel, which would have indicated whether the gear had locked down, didn't illuminate because of the electrical problem. (The pilot didn't perform the emergency-gear-extension procedure, which involves using a hand pump until there's heavy resistance.)

Although the focus of the NTSB's safety recommendation was an Airbus A320, reports filed by pilots to NASA's Aviation Safety Reporting System (ASRS) prove that there's a broader issue in play. [Turn to "True Confessions" on page 64 for more information about the ASRS and its role in maintaining air safety.] Some of the more than 400 reports I found show the importance of carrying portable equipment to provide communication and navigation redundancy. While not all of these reports involve aircraft with glass cockpits, they do serve to establish that in-flight electrical problems aren't exactly rare.

The pilot of a Cherokee Six and his family were about an hour into a pleasure flight (in instrument conditions) when the plane experienced an electrical failure. The pilot decided to return to the departure airport. He had a handheld GPS unit as a backup he could use for navigating and for viewing weather radar, and also a handheld transceiver. He declared an emergency using the handheld radio, but couldn't get a response from the controller who had been handling the flight. The pilot tried using the emergency frequency, 121.5, but was unsuccessful. His wife dialed (800) WXBRIEF on her cell phone, but she couldn't get through; she did, however, reach a 911 operator. She asked the operator to call the FAA and tell them that the flight had experienced an electrical failure and was returning to the departure airport. About 10 minutes out, the pilot made contact with the airport's control tower and was cleared for a straight-in approach. The pilot wasn't sure whether the gear had extended, and requested a flyby of the tower. The controller advised that the gear was up and cleared a block of airspace for the pilot to use in the hopes of getting the gear to drop. A repeat flyby confirmed that the gear was down, and an uneventful landing followed.

The electrical system on an Airbus A320 consists of two main alternating current (AC) busses that are connected to several other busses to carry AC throughout the airplane. There are also direct current (DC) busses that carry DC, which is produced by passing AC through a transformer-rectifier unit. The auxiliary power unit (a small jet engine) can also produce electrical power, as can an air-driven emergency generator. If there's a problem with one of the electrical busses, the system can be reconfigured to get power from other busses to where it's needed. Reconfiguration must be performed manually by the pilots.

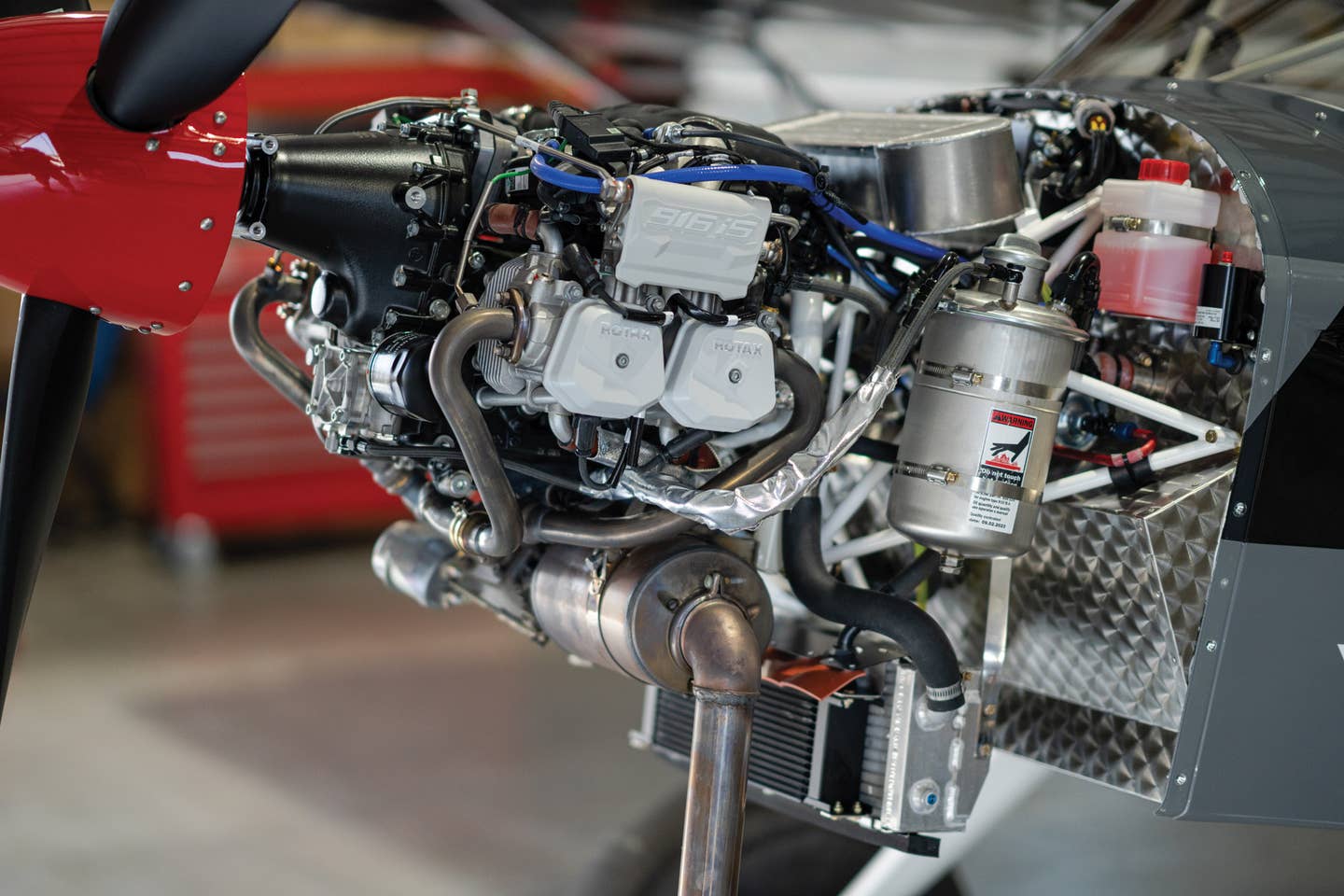

The electrical system on a light GA aircraft is simpler than that of a transport-category jet. Still, the pilot should have a solid understanding of how the system is designed and what procedures to follow in case of a malfunction. Power sources generally consist of a storage battery and an alternator or generator on each engine. If the airplane has a glass cockpit, then there will generally be a standby battery for the flight displays and various processors that gather and process the data in order to produce the images. Backup instruments, such as an attitude indicator, may have their own standby batteries. A systemic power loss will generally cause the standby batteries to switch on so that one or more display screens keep operating with basic information. How long they'll last depends on factors such as system design, battery age and charge, and operating environment.

Even though an Airbus A320's electrical system is markedly different from that of most light GA aircraft, the overall experience for the pilots of the A320 operated by United Airlines was similar to what pilots of a GA aircraft with a glass cockpit might undergo. The pilots had to figure out what was going on, whether it was worthwhile to find a solution by troubleshooting, and the best way to maintain aircraft control while getting back on the ground as expeditiously as possible.

At 9:45 a.m. on January 25, 2008, United Flight 731 departed from Newark Liberty Airport in Newark, N.J., on a flight to Denver, Colo., with 107 people on board. Shortly, after lifting off, three of the six electronic panel displays went blank---including the captain's PFD and navigational display, plus the upper electronic centralized aircraft monitoring (ECAM) display---and a number of systems became inoperative. The attitude information on the first officer's PFD became unusable, though it eventually returned. The landing-gear handle had been moved to the "retract" position (as is normally done after takeoff), but the gear stayed down.

All radios became inoperative and the airplane's transponder, traffic alert and collision avoidance system (TCAS) and standby attitude indicator all went dead. One interesting (and perhaps frightening) bit of information is that the A320's standby attitude indicator is designed to function for only five minutes after it loses power. (Its usefulness is particularly limited in the event of a catastrophic electrical failure while in night VFR over the middle of the ocean.) The NTSB wants the FAA to require that the standby attitude indicators run for at least 30 minutes.

The first officer reported that the standby attitude indicator began to present false information about three minutes after takeoff, rolling about 45 degrees and pitching up about 20 degrees. Eventually, an orange "failure" flag appeared. The first officer stated, "If Newark had low ceilings and visibility that day, and if my attitude indication on my PFD hadn't returned, the aircraft may have been lost as the attitude gyro failed." In a report to ASRS, the first officer stated, "As I continued to fly straight ahead, I had little idea what was wrong with the aircraft! The captain told me of his confusion with what was happening to the airplane. Neither of us really understood what had happened."

The pilots leveled Flight 731 at 2,500 feet, the first assigned altitude on their IFR flight plan. Crew members reported feeling a very real urgency to land because the aircraft was at low altitude in VFR conditions, not in contact with ATC, had an inoperative transponder and was heading roughly in the direction of downtown Manhattan. (We all remember September 11, 2001: Two airliners, one a Newark departure, flew to downtown at low altitude in VFR conditions without radio or radar contact with ATC.) "I made a comment to the captain about staying clear of the metropolitan area, not wanting to get shot down by military fighters," reported the first officer. "I wasn't joking at all. Operating this ’no radio' aircraft with no ’squawk' at low altitude made me quite uncomfortable."

The crew felt that the sense of urgency may have led them to devote most of their efforts toward returning to Newark rather than troubleshooting the aircraft's problems. After a safe landing at Newark, the crew was able to focus on troubleshooting; they manually moved one of the AC bus feeds to "alternate," which reconfigured the power supply. At this point, the captain's instruments and most of the failed aircraft systems started working again.

The NTSB found that in May 2007, Airbus had issued a service bulletin to modify the electrical system so that the AC power supply would be automatically reconfigured in the event of a failure affecting the #1 bus. The FAA didn't issue an airworthiness directive to mandate compliance, which the NTSB says it should now do. The Flight 731 aircraft hadn't been modified. The NTSB also said the FAA should require better guidance and more simulator training about dealing with electrical malfunctions for Airbus A320 pilots.

Peter Katz is editor and publisher of NTSB Reporter, an independent monthly update on aircraft accident investigations and other NTSB news. To subscribe, write to: NTSB Reporter, Subscription Dept., P.O. Box 831, White Plains, NY 10602-0831.

Subscribe to Our Newsletter

Get the latest Plane & Pilot Magazine stories delivered directly to your inbox