Anti-Icing: A Bioengineering Approach

Researchers are looking toward the animal and plant kingdoms, and coming up with ingenious ways to stop airframe icing

As the old saying goes, if folks were meant to fly, they would have been born with wings. I might add that if they had been intended to attempt flight through icing conditions, they would have been blessed with dimpled wings like the Namib desert beetle or coated with a slippery substance like the carnivorous pitcher plant.

Well, maybe. But, if we weren't actually born with all that stuff, maybe we can at least take some notes from nature the same way that our aviation forebears did by watching birds.

Welcome to one of the hottest research areas in engineering: Biomimetics. It's the science of looking at nature's engineering and applying those designs to human problems. Class is in session.

LESSON ONE: FROST IN THE DESERT AND ON YOUR WINGS

Airliners and bizjets have the luxury of plenty of hot air coming from the engines. Redirect that to your wings and windshield, and you can keep that water in its liquid state.

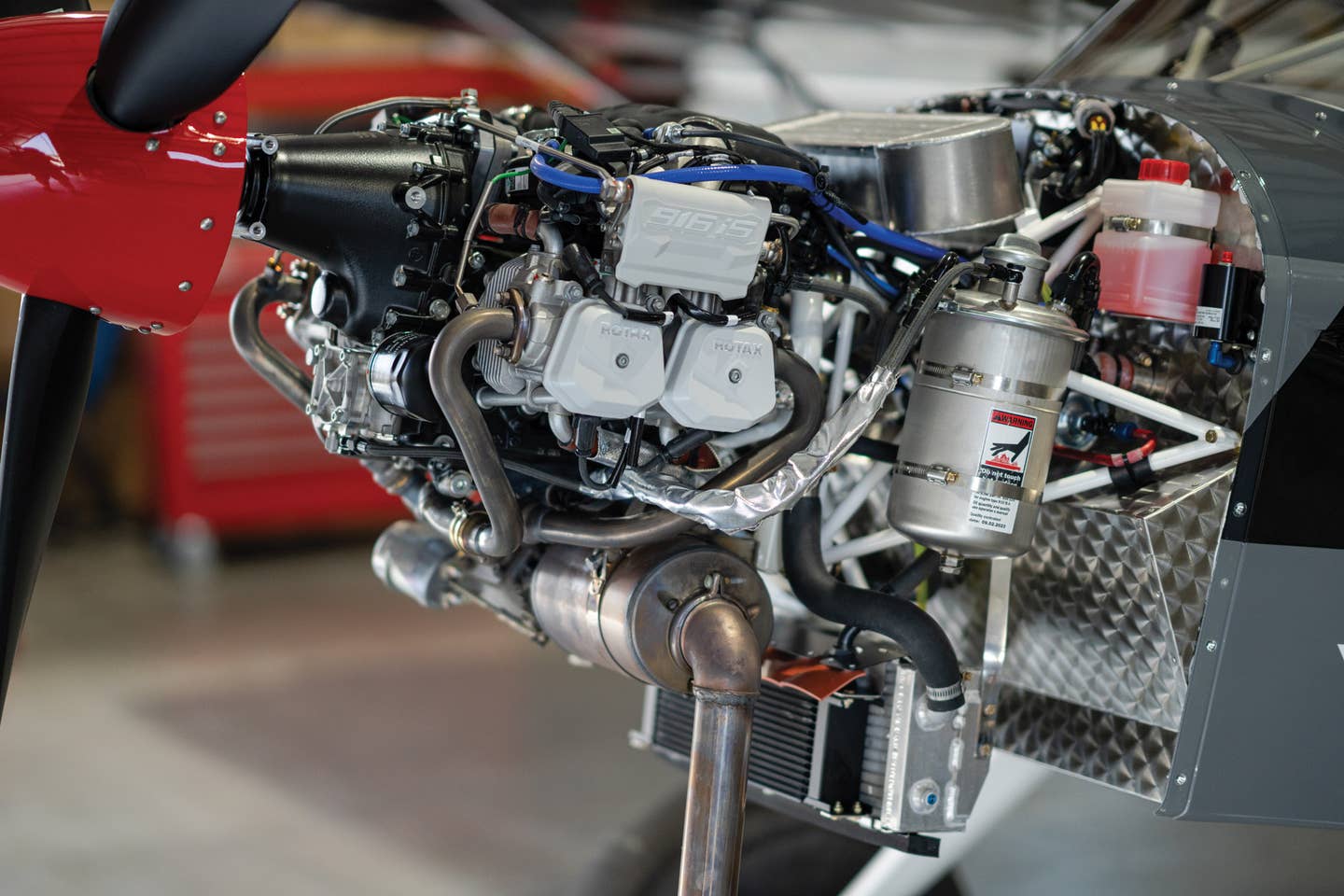

For small aircraft, icing conditions have been a killer problem with no simple solution. A bleed-air system would be too complex and heavy. So, the few planes that are certified for flight into known icing conditions use pneumatic air bladders to inflate and break away ice. Or, they spray glycol on the wings to melt away ice.

Instead of these active systems, wouldn't it be great if there were a completely passive anti-ice answer? In other words, the pilot doesnothing, but the wings stay clean in any condition.

To the desert, we go, for ideas! Why look in a desert when there's no need to worry about frost there? Well, frost is just condensed water, and desert animals have become experts at collecting that scarce resource. Let's take a look at how they do it.

On foggy mornings (or conditions that pass for fog in the desert, or even just in humid air), the Namib desert beetle stretches its wings toward the prevailing breeze to catch tiny water particles. Bumps that attract water dot the outer surface of the beetle's wings. The irregular surface of the bumps interacts with water in the air, creating air pockets as minuscule molecules hit, causing them to stick. It's what's called a hydrophilic surface. As the water begins to collect, its weight grows until it rolls off the bump, and into a flat, waxy valley---the hydrophobic expressway that flows straight to the beetle's mouth. Clever!

Double-clever is how Jonathan Boreyko, a researcher and assistant professor of Biomedical Engineering and Mechanics at Virginia Tech's College of Engineering, applied that freshman biology case study strategy to the exactly opposite problem of frost.

Prior to Boreyko's research, it was thought that frost forms from a bunch of dew droplets that freeze individually as they sit on a subfreezing surface. Boreykodiscovered what really happens is that a single drop freezes first. Then, ice bridges begin forming between that drop and surrounding dewdrops that are still liquid. The tiny bridges use water from the liquid drops, building a frozen mesh.

Photos courtesy of the Aizenberg Lab/Harvard SEAS

Using the beetle example, Boreyko wondered whether he could control the dew pattern, keeping drops far enough apart so that neighboring drops run out of liquid before they can bridge across to the nearby frozen drop.

He tested the idea by laying down his own hydrophilic pattern with chemicals. Not only did no ice bridges form, but the single, frozen droplet became surrounded by a dry zone: The liquid drops evaporated as they built a bridge that reached only into the air.

Could the same idea apply to larger surfaces, like your Piper Arrow, sitting overnight on the ramp in Denver? Theoretically, yes, but what's good at preventing frost doesn't address freezing rain in flight.

So, slow down. We have another lesson before we can put this all together.

LESSON TWO: THE ORIGINAL LOW-ALTITUDE BUG KILLER

Consider the pitcher plant. It's beautiful to look at, particularly if you're an ant or other crawly bug in search of a few tasty morsels. The pitcher plant leaves form a deep, enclosed vase, at the very base of which just might be a snack.

So, the bugs crawl on until rain or dew or fog adds a little moisture to the equation. Suddenly, the pitcher plant's leaves become super-slippery. The bugs lose their footing, fall to the bottom of the pitcher, and encounter some nasty fluid there that drowns and digests them. It's nature's oldest story: If you don't know what the snack is today, maybe it's you.

What's going on here? It turns out the pitcher plant has a micro-scale roughness on its leaves that makes for easy, dry footing. When moisture hits that roughness, it clings to it (just like the water droplets on the beetle's wings). In this case, that adhesion forms a wet, top layer: It's the

waterslide of arthropod death.

Such super-slipperiness inspired Harvard researchers who were searching not for snacks, but rather for surfaces that might repel contaminants: water, oil, barnacles, and even for our aeronautical purposes, ice.

Taking nature's cue, the Harvard researchers, led by Professor Joanna Aizenberg, developed a process in which they coat a surface with a thin layer of roughness. Then, they inject a proprietary liquid onto the scratchy surface, where it bonds tightly and is held in place. The result is called a "slippery liquid-infused porous surface," or SLIPS, and it's pretty magical.

Spray some super-cooled, liquid water on a sheet of SLIPS-treated aluminum and it slides off before it has a chance to freeze. Even if ice forms, it's helpless to cling to the metal.

Aizenberg and her fellow materials scientists are so stuck on the idea that they founded their own startup called SLIPS Technologies to commercialize it.

Photo by David Eickhoff/Wikimedia Commons

The one wild card in the whole process is the question of drag, which the researchers admit is still somewhat of an unknown. The very irregularities that restrict the formation of ice may very well disrupt, to some degree, the unimpeded flow of air over the lifting surface. That said, other forms of anti-icing technology popular on planes without bleed air as an option are pretty draggy, too. The addition of TKS panels to the leading edge of a Cirrus wing, for example, adds up to 5 knots of drag at cruise, and the addition of pneumatic boots can be just as bad for aerodynamic efficiency, or worse. So, even if there's a negligible drag penalty, the good news is that it's unlikely to be any worse than current solutions.

So, can we have our frost-resistant, super-slippery airframes already? Well, maybe. Eventually.

FINAL EXAM AND EXTRA CREDIT: COMPARE, CONTRAST AND SYNTHESIZE

As Professor Boreyko explains it, there are three challenges to overcome between laboratory and liftoff. The first is scalability. What works with a single frozen droplet under Boreyko's microscope has to be proven over large surfaces. And, it has to scale in a cost-effective way. We can't pay researchers to apply nano-lithography to our leading edges, so commercial methods must be developed.

At the University of Michigan, a research team may be able to help. They decided that it may be faster and more cost-effective to exploit "rubberyness" to break the bond between ice and an underlying surface. Ice doesn't grip rubbery surfaces well, due to a combination of slipperiness and stiffness. By fine-tuning the combination of those qualities, Professor Anish Tuteja and his students created more than 100 different polymercoatings, called elastomers, for specific purposes. Recently, they passed ice-shedding tests in outdoor Michigan winter conditions. Most significantly, the polymer recipes were produced from readily available, existing commercial materials.

Spray some super-cooled, liquid water on a sheet of aluminum and it slides off before it has a chance to freeze. Even if ice forms, it's helpless to cling to the metal.

The second challenge is durability. What happens to a liquid-infused surface over time? Boreyko points out that if anything ever does freeze onto one of these surfaces, its surface friction tends to wick away the surface layer. There's also the question of how well that infused liquid stays bonded while traveling through a slipstream at Boeing speeds.

Last, there's the question of integration. The solution that finds its way to our wings is likely to be a combination of technologies: frost-fighting etched patterns in combination with SLIPS-like liquid-infused surfaces or elastomer coatings. It will take time to assemble all the research into a cohesive approach.

Still, says Boreyko, "At the pace we're going, it's at least plausible that in five or 10 years, the three challenges could be more or less solved. Still, there's certainly a lot of work left to do."

In other words, the technology is promising, but there are still a few bugs to be worked out. A commercial pilot with instrument privileges, Grant Opperman is a writer and business strategy consultant who flies himself to more than 20 states across the U.S. for business and pleasure.

A commercial pilot with instrument privileges,Grant Opperman is a writer and business strategyconsultant who flies himself to more than 20 statesacross the U.S. for business and pleasure.

Subscribe to Our Newsletter

Get the latest Plane & Pilot Magazine stories delivered directly to your inbox